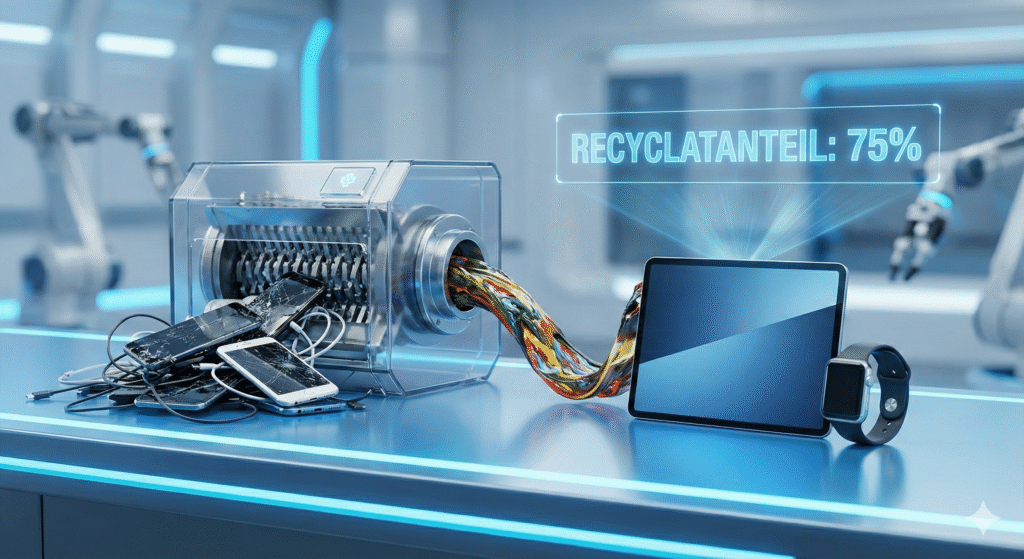

In an era defined by rapid technological advancement, we face a paradoxical challenge. While our devices become faster, smarter, and sleeker, the environmental cost of producing them continues to mount. Every year, millions of tons of electronic waste are discarded, creating a crisis that demands immediate attention. This is where the concept of recyclatanteil steps into the spotlight as a game-changer for the technology sector. Although the term originates from German, meaning “share of recycled content,” it has become a universal metric for sustainability in global manufacturing, specifically within the European Union and eco-conscious markets.

Understanding recyclatanteil is no longer just for supply chain managers or environmental scientists; it is crucial for every consumer who buys a smartphone, laptop, or smart home device. It represents the percentage of secondary raw materials used to create a new product, effectively measuring how much of your new gadget had a previous life. By prioritizing devices with a high recycled share, we reduce the demand for virgin resource extraction, lower energy consumption, and close the loop on the circular economy. This article will dive deep into the mechanics of recycled content in tech, exploring why it is the most critical specification you should look for in 2026 and beyond.

Defining Recyclatanteil in the Tech Ecosystem

At its core, recyclatanteil refers to the proportion of recycled material contained within a product compared to its total mass. In the tech industry, this is not a single number but a complex aggregate of various materials including plastics, metals, and glass. For a device to be truly sustainable, manufacturers must source high-quality secondary materials that meet rigorous durability standards.

The measurement usually focuses on specific components:

- Chassis and Casings: Often made from recycled aluminum or polycarbonate.

- Internal Brackets: Frequently utilize reclaimed steel or magnesium.

- Packaging: High percentages of recycled paper and cardboard.

- Keycaps: Increasingly made from Post-Consumer Recycled (PCR) plastics.

The Urgent Battle Against E-Waste

The tech industry is the fastest-growing waste stream on the planet. We consume electronics at a voracious pace, leading to mountains of discarded circuit boards and plastic shells. Increasing the recyclatanteil in new devices creates a financial incentive to harvest this waste. If manufacturers need old plastic to make new phones, “trash” suddenly becomes a valuable commodity.

Why this metric fights waste effectively:

- Market Demand: It creates a pull market for recycling facilities.

- Landfill Diversion: Keeps tonnages of plastic and heavy metals out of the ground.

- Resource Conservation: Slows the depletion of finite elements like copper and gold.

Post-Consumer vs. Post-Industrial Recyclates

Not all recycled content is created equal. When analyzing the recyclatanteil of a gadget, it is vital to distinguish between Post-Consumer Recycled (PCR) and Post-Industrial Recycled (PIR) materials. PCR comes from items you and I have thrown in the recycling bin, while PIR comes from factory scraps that never left the manufacturing floor.

Key differences include:

- PCR (Post-Consumer): High environmental impact; closes the loop on end-of-life products.

- PIR (Post-Industrial): Easier to process but less impactful regarding consumer waste reduction.

- Processing Complexity: PCR requires more cleaning and sorting than PIR.

- Availability: PIR is cleaner and more consistent; PCR supply fluctuates.

The Revolution in Smartphone Materials

Smartphones are perhaps the most visible battleground for increasing recycled content. Leading brands are now competing not just on camera megapixels, but on who has the greener phone. Achieving a high recyclatanteil in smartphones is difficult due to the need for structural integrity and thermal management in a tiny form factor.

Current innovations include:

- Recycled Rare Earth Elements: Used in the magnets of speakers and haptic engines.

- reclaimed Tungsten: Often found in the vibration motor mechanisms.

- Solder: Utilizing 100% recycled tin on the main logic boards.

- Antenna Bands: Manufactured using upcycled water bottles transformed into high-grade plastic.

Laptop Manufacturing and Aluminum Loops

Laptops require robust casings to protect delicate screens and processors. Traditionally, this meant mining virgin bauxite to create aluminum. However, the shift toward a higher recyclatanteil has led to the development of recycled aluminum alloys that are indistinguishable from virgin metal in terms of strength and aesthetics.

The benefits of recycled aluminum in laptops:

- Energy Savings: Recycling aluminum saves up to 95% of the energy needed to mine it.

- Carbon Footprint: Drastically lowers the embodied carbon of the chassis.

- Aesthetics: Modern techniques ensure no loss in the premium “feel” or finish.

The Challenge of Quality and Durability

A common myth is that products with a high recyclatanteil are fragile or of lower quality. In the early days of recycling, this might have been true, but chemical engineering has advanced significantly. Today, compounded recycled plastics are reinforced with additives to match the performance characteristics of virgin plastic.

Ensuring durability involves:

- Strict Testing: Drop tests and thermal cycling remain identical for recycled and virgin parts.

- Hybrid Blends: Mixing PCR with a small percentage of virgin plastic to ensure consistency.

- Material Science: Developing new polymers specifically designed to be recycled multiple times.

EU Regulations Driving the Change

The European Union is the driving force behind the adoption of the term “recyclatanteil.” The Ecodesign Directive and the proposed Digital Product Passport are setting strict minimums for recycled content. If a tech company wants to sell in Europe, they must comply, which effectively forces global changes since companies rarely make separate products for different continents.

Regulatory impacts include:

- Mandatory Minimums: Legal requirements for percentage of recycled plastic.

- Transparency: Brands must disclose the exact makeup of their materials.

- Taxation: Potential taxes on virgin plastics to incentivize recycled alternatives.

Financial Implications for Tech Giants

Initially, integrating a higher recyclatanteil was expensive due to the lack of supply chains. However, as the infrastructure for collecting and processing e-waste matures, the economics are shifting. While high-purity PCR plastic can still command a premium, the risk mitigation it offers against volatile raw material prices is invaluable.

The economic landscape:

- Supply Chain Stability: Less reliance on mining geopolitics.

- Brand Value: Consumers are willing to pay a premium for “green” products.

- Long-term Savings: Reduced energy costs in processing metals like aluminum.

Consumer Perception and Greenwashing

As recyclatanteil becomes a marketing buzzword, consumers must be wary of greenwashing. Some companies might claim a product is “made from recycled materials” when only a tiny screw or a single component is recycled. Authentic sustainability requires transparency about the total percentage by weight.

How to spot the truth:

- Specific Claims: Look for “30% recycled plastic in the housing,” not vague “eco-friendly” labels.

- Third-Party Verification: Trust labels like UL Solutions or TCO Certified.

- Holistic Approach: Does the company also offer a repair program?

The Role of Packaging in the Equation

While the device itself is important, the box it comes in is the first thing a consumer touches. The tech industry has rapidly moved toward 100% recyclatanteil in packaging, eliminating plastic wraps and foams in favor of molded fiber and recycled cardboard. This is the “low hanging fruit” of sustainability.

Innovations in packaging:

- Molded Pulp trays: Replacing styrofoam with recycled paper sludge.

- Soy Inks: Printing on boxes without toxic chemicals that hinder recycling.

- Plastic-Free Seals: Using paper tear-strips instead of shrink wrap.

Rare Earth Elements: The Final Frontier

Recovering gold, cobalt, and lithium involves complex chemical processes. These materials are crucial for batteries and processors but have historically had a near-zero recyclatanteil due to the difficulty of extraction from old devices. New robotic disassembly plants are beginning to change this, automating the harvesting of magnets and batteries.

Why this matters:

- Strategic Independence: Reduces dependence on mining in conflict zones.

- Toxicity: Prevents heavy metals from leaching into soil at landfills.

- Efficiency: Urban mining (recycling) yields more gold per ton than traditional mining.

Ocean-Bound Plastics in Tech

A specific subset of recyclatanteil that has gained popularity is “ocean-bound plastic.” This is waste collected from within 50km of a coastline in areas lacking waste management. By using this material, tech companies prevent it from entering the oceans. It tells a compelling story and cleans up the environment simultaneously.

Applications in tech:

- Speaker Fabric: Mesh covers woven from processed fishing nets.

- Fan Housings: Internal cooling fans made from collected plastic bottles.

- Laptop Bezels: Structural frames utilizing mixed ocean plastics.

Comparison: Virgin vs. Recycled Materials

To understand the tangible impact of choosing products with high recycled content, we must look at the data. The energy and carbon savings are often drastic, particularly for metals and plastics used heavily in consumer electronics.

| Material Type | Energy Savings (vs. Virgin) | CO2 Reduction | Cost Factor |

| Aluminum | ~95% | High | Lower/Neutral |

| Copper | ~85% | Moderate | High (Processing) |

| Plastic (PET) | ~80% | Moderate | Variable |

| Gold | ~98% | Very High | Lower |

Certifications You Should Know

If you want to ensure the recyclatanteil claims are legitimate, you need to know which logos to look for. Self-declared environmental claims are often unreliable. Independent certification bodies audit the supply chain to prove that the materials are indeed recycled.

Key Certifications:

- EPEAT: A global rating system for greener electronics.

- TCO Certified: Focuses on social and environmental sustainability in IT.

- Blue Angel (Blauer Engel): The German certification that heavily weighs recycled content.

- Global Recycled Standard (GRS): Verifies the recycled content of the final product.

The Supply Chain Logistics Nightmare

Increasing the share of recycled materials is a logistical beast. Unlike mining, where you dig in one place, recycling requires gathering waste from millions of individuals. This “reverse logistics” is the biggest hurdle to achieving 100% recycled devices. Manufacturers must build networks to take back old devices efficiently.

Logistical steps involved:

- Collection: Retail take-back programs and mail-in services.

- Sorting: Using AI to identify plastic types.

- Cleaning: Removing contaminants like glue, labels, and oils.

- Pelletizing: Turning waste back into raw manufacturing beads.

Future Outlook: The Circular Economy

The ultimate goal is a 100% closed-loop supply chain where no new materials are extracted from the earth. While we are not there yet, the steady increase in recyclatanteil year over year is the metric that proves we are moving in the right direction. Future tech will be designed for disassembly, making it easier to keep these materials in the loop forever.

Trends to watch:

- Modular Design: Phones that can be taken apart by hand.

- Bio-plastics: Mixing recycled content with plant-based materials.

- Leasing Models: Companies retaining ownership of the hardware to ensure recycling.

Frequently Asked Questions

What is a “good” percentage of recyclatanteil in a new laptop?

Currently, a device with a recyclatanteil (recycled content) of over 30% for the total product weight is considered excellent. For specific parts like the aluminum chassis, you should look for 90% to 100%. However, reaching high percentages for plastic components is harder, so 30-50% is the industry standard there.

Does high recycled content affect the durability of my phone?

No, it should not. Modern reprocessing techniques allow recycled plastics and metals to meet the same structural engineering standards as virgin materials. Major manufacturers perform rigorous drop tests and stress tests to ensure that the recycled parts perform identically to new ones.

Why are some tech companies hesitating to use 100% recycled materials?

The main barriers are availability and purity. There is simply not enough high-quality Post-Consumer Recycled (PCR) plastic available to meet the massive demand of the global tech industry. Additionally, technical challenges regarding color consistency and material strength in thin parts prevent a jump to 100% immediately.

How can I verify the recyclatanteil claims of a brand?

Always look for third-party certifications rather than just marketing text. The Global Recycled Standard (GRS) and UL Validation are trustworthy markers. Furthermore, check the product’s official “Environmental Report” or “Eco-sheet” on the manufacturer’s website for a detailed breakdown.

Is recycled plastic cheaper for companies to use?

Surprisingly, high-quality recycled plastic is often more expensive than virgin plastic. This is due to the costs associated with collecting, sorting, cleaning, and reprocessing the waste. When you buy a product with high recycled content, you are supporting the infrastructure needed to lower these costs in the future.

What is the difference between “recyclable” and “recycled content”?

These terms are often confused. “Recyclable” means the product can be turned into something else after you are done with it. “Recycled content” (or recyclatanteil) means the product was made from waste materials. A product can be 100% recyclable but contain 0% recycled content.

Does the battery contain recycled materials?

Historically, no, but this is changing rapidly. New EU regulations are pushing for mandatory recycled cobalt, lead, and lithium in batteries. While current percentages are low, the industry is scaling up “urban mining” capabilities to recover these critical minerals from old batteries for use in new ones.

Conclusion

The transition to a circular economy is the most significant shift in the technology sector since the invention of the microchip. Recyclatanteil is the yardstick by which we measure this progress. It moves us away from the linear “take-make-waste” model toward a future where our technological hunger does not devour the planet’s resources. As we have explored, the integration of recycled aluminum, plastics, and rare earth elements is not just an environmental necessity; it is a testament to human ingenuity and engineering prowess.

For the consumer, the power lies in the purchase. By choosing devices with a documented, high share of recycled content, you send a clear signal to manufacturers that sustainability is a non-negotiable feature. We are standing at the threshold of a new era in electronics one where high performance and environmental responsibility are no longer mutually exclusive. As regulations tighten and technology evolves, the recyclatanteil of our devices will continue to climb, paving the way for a greener, cleaner digital world.