Introduction

In the high-stakes world of precision manufacturing, the integrity of tooling is paramount. Molds are the backbone of mass production, from intricate medical devices to massive automotive components. However, these expensive assets degrade over time or require design updates due to shifting market demands. Enter the domain of “repmold“the sophisticated technological process of repairing, modifying, and revitalizing industrial molds. Gone are the days of crude patchwork; today’s repmold techniques utilize cutting-edge technologies like laser photonics and digital twinning to extend tool life and ensure absolute precision. This article explores how embracing modern repmold strategies solves critical production bottlenecks, saves substantial capital, and keeps manufacturing agile in a competitive landscape.

Defining Repmold in Modern Tech

Repmold is no longer just about fixing a crack; it is a comprehensive technological discipline involving the restoration or modification of complex tooling. In the context of modern Industry 4.0, it bridges the gap between a worn-out asset and a high-performance production tool. It involves a suite of precise technologies designed to add material, remove defects, or alter geometry without compromising the base integrity of the mold.

- Scope: Covers injection molds, die casting dies, and stamping tools.

- Goal: Restoring original specifications or implementing engineering changes (ECs).

- Tech Integration: Combines physical welding with digital design data.

The Evolution of Mold Repair

Traditionally, repairing a damaged mold meant using stick welding, which often introduced excessive heat. This “heat-affected zone” (HAZ) caused warping, leading to significant post-repair machining and often permanent tool degradation. The evolution toward modern repmold techniques has been driven by the need to minimize thermal distortion.

- Past: High heat input, high risk of distortion, manual processes.

- Present: Low heat input, microscopic precision, automated solutions.

- Result: Repairs are now often indistinguishable from the original base metal.

Why Mold Maintenance Matters Digitally

In an era driven by data, physical tooling must align with digital models. Repmolding is essential for maintaining this digital-physical synchronization. If a physical mold wears down and produces out-of-spec parts, it no longer matches its CAD master file, disrupting the entire quality control chain.

- Digital Twin Alignment: Ensuring the physical tool matches its virtual counterpart.

- Predictive Maintenance: Using sensor data to schedule repmold activities before failure.

- Quality Assurance: Maintaining tight tolerances for automated assembly lines.

Laser Welding Technologies

Laser welding is arguably the most significant advancement in repmold technology. By utilizing highly focused beams of light, technicians can melt filler material onto the mold surface with pin-point accuracy. The energy is concentrated in such a small area that the surrounding metal barely heats up, effectively eliminating common distortion issues.

- Precision: Capable of welds as small as 0.1mm in diameter.

- Minimal HAZ: Protects critical surfaces and intricate details nearby.

- Versatility: Effective on various tool steels, aluminum, and beryllium copper alloys.

Micro-TIG Welding Applications

While lasers dominate ultra-fine work, Micro-TIG (Tungsten Inert Gas) welding remains a vital repmold technique for slightly larger repairs. Modern Micro-TIG units offer pulsed arc controls that significantly reduce heat input compared to traditional TIG welding, providing a middle ground between heavy-duty welding and laser precision.

- Application: Ideal for building up larger worn areas, such as parting lines or edges.

- Control: Advanced power sources allow for precise management of the weld puddle.

- Cost-Effective: generally lower equipment costs compared to high-end laser systems.

The Role of CNC Machining

Once material has been added via welding, it must be shaped back to the exact contours of the mold. Computer Numerical Control (CNC) machining is crucial in the repmold workflow. High-speed milling centers re-cut the welded areas to match the original CAD data precisely.

- Accuracy: Restores complex 3D surfaces to micron-level tolerances.

- Surface Finish: Modern CNC machines can achieve near-polished finishes, reducing manual benchwork.

- Integration: Directly utilizes updated CAD files for engineering changes.

EDM (Electrical Discharge Machining) Insights

For deep ribs, sharp corners, or hardened steel areas that traditional cutting tools cannot reach, Electrical Discharge Machining is indispensable. In repmolding, “sinker” EDM uses a shaped electrode to erode unwanted material or reshape welded areas in difficult-to-access cavities.

- Hard Material Capability: Easily machines hardened tool steel (over 60 HRC) without thermal stress.

- Intricate Detail: Essential for restoring fine textures or sharp internal radii.

- Non-Contact: The process puts no cutting force on the mold, preventing deflection.

Integrating CAD/CAM Data

Modern repmold processes are data-driven. The workflow begins and ends with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM). When an engineering change is required, the new CAD data dictates exactly where material must be added and subsequently removed.

- Version Control: Managing different iterations of tool designs to ensure the correct modification.

- Simulation: CAM software simulates machining paths to prevent collisions during the repair.

- Verification: Comparing final scanned results back to the CAD master.

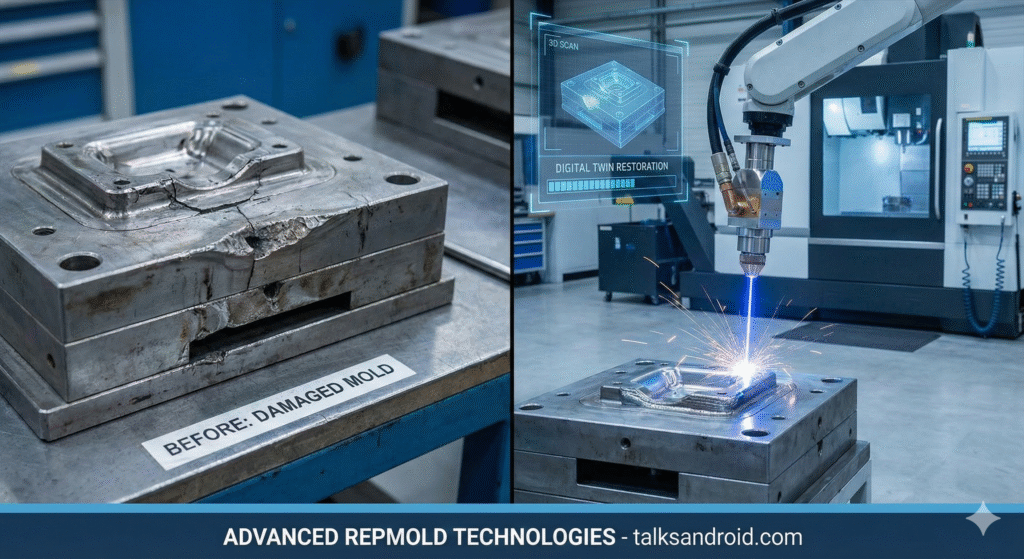

3D Scanning for Reverse Engineering

Often, older molds lack reliable CAD data. Here, 3D scanning technology plays a pivotal repmold role. By creating a high-resolution digital point cloud of the existing physical mold, engineers can reverse-engineer a new CAD model to serve as the baseline for repairs or modifications.

- Data Capture: Non-contact blue light or laser scanners capture complex geometries rapidly.

- Wear Analysis: Overlaying scan data on original CAD reveals exact areas of erosion.

- Archiving: Creating digital backups of legacy tooling assets.

Additive Manufacturing in Repmolding

Additive manufacturing (3D printing) is beginning to complement traditional repmold techniques. Direct Energy Deposition (DED) is a process where metal powder is fused by a laser layer by layer, allowing for the buildup of significant features on existing tool bodies.

- Hybrid Manufacturing: Combining additive buildup with subtractive CNC machining in one setup.

- Complex Cooling: Adding conformal cooling channels to the exterior of existing inserts.

- Rapid Material Addition: Faster than wire welding for large volumetric repairs.

Material Science Considerations

A successful repmold project depends heavily on metallurgical compatibility. The filler material used during welding must match the base mold steel thermally and chemically. Using incompatible materials can lead to cracking during thermal cycling in production or differences in polishing rates that affect part finish.

- Matching Hardness: Ensuring the weld area can be heat-treated to the same hardness as the base tool.

- Thermal Expansion: Matching coefficients to prevent stress fractures during heating and cooling cycles.

- Polishing Characteristics: Critical for molds requiring high-gloss mirror finishes.

Digital Twin Technology for Tooling

The “Digital Twin” concept is the ultimate realization of modern repmold strategies. It is a dynamic, virtual representation of the physical mold that accumulates data throughout its lifecycle. Every repair, modification, and production cycle is logged, allowing engineers to predict when the next repmold intervention will be necessary.

- Lifecycle Tracking: A complete history of every weld and modification performed.

- Performance Simulation: Testing how a proposed modification will affect mold flow and cooling physically.

- Proactive Management: Moving from reactive repairs to scheduled technological interventions.

Automation in Mold Modification

To increase consistency and reduce reliance on highly skilled manual labor, automation is entering the repmold sector. Robotic arms equipped with laser cladding heads or automated polishing systems ensure that repairs are performed identically every time, removing human variability.

- Repeatability: Essential for multi-cavity molds where every cavity must be identical.

- 24/7 Operation: Automated systems can perform long cladding operations overnight.

- Skill Gap Solution: Addressing the shortage of veteran tool and die welders.

Comparing Repair Techniques

Choosing the right technique depends on the damage severity and the mold’s requirements. Below is a comparison of the two most prominent welding technologies used in repmolding today.

Table 1: Laser Welding vs. Micro-TIG Technology

| Feature | Laser Welding Tech | Micro-TIG Tech |

| Heat Affected Zone (HAZ) | Extremely Small (Microns) | Small/Medium |

| Precision Level | Ultra-High (Fine details) | High (Edges/Profiles) |

| Distortion Risk | Negligible | Low |

| Deposition Rate | Slower | Faster |

| Primary Use Case | Pinholes, textured surfaces, sharp corners. | Parting line buildup, larger wear areas. |

Cost-Benefit Analysis of Repair vs. Replace

The decision to utilize repmold services versus commissioning a new tool is primarily economic. A complex, multi-cavity injection mold can cost upwards of $100,000 and take months to build. A high-tech repair might cost 5-10% of that and take only days.

- Lead Time: Repmolding saves weeks or months of production downtime compared to building new.

- Asset Utilization: Maximizing the ROI on the initial tooling investment.

- Sustainability: Repairing is inherently more environmentally friendly than scrapping tons of tool steel.

Case Study: Automotive Sector

A Tier-1 automotive supplier faced a crisis: a design change on a dashboard component required moving a mounting clip feature by 3mm on a massive, hardened steel injection mold.

- The Challenge: Building a new mold would take 12 weeks and cost $80,000. Stick welding would warp the precision shut-offs.

- The Repmold Solution: Using laser welding technology, technicians built up the old feature area using a matching H13 tool steel filler. CNC machining redistributed the area to the new specifications.

- The Result: The mold was back in production in 5 days at a cost of $6,500, with zero flash or dimensional issues on the final parts.

Future Trends in Tooling Tech

The future of repmold lies in deeper integration with Artificial Intelligence. AI algorithms will soon analyze 3D scan data of worn molds and automatically generate the optimal toolpaths for both laser cladding deposition and subsequent CNC machining, making the process nearly autonomous.

- AI-Driven Path Planning: Optimizing repair strategies automatically.

- In-Situ Monitoring: Real-time quality checks during the welding process using sensors.

- Virtual Reality (VR): Allowing technicians to inspect mold damage remotely.

Choosing the Right Repmold Partner

Not all tool shops possess the necessary technology for modern repmolding. Selecting a partner requires vetting their technological capabilities. Look for facilities that have in-house laser systems, comprehensive CAD/CAM capabilities, and a deep understanding of metallurgy.

- Technology Audit: Do they rely on traditional welding or modern laser/micro-TIG?

- Digital Workflow: Can they handle complex surface data and 3D scanning seamlessly?

- Experience: Do they have a track record with your specific mold materials and industry requirements?

FAQs Section

What is the biggest advantage of modern repmold tech over traditional repair?

The primary advantage is the drastic reduction of heat input. Technologies like laser welding minimize thermal distortion, meaning the mold retains its original dimensions outside the immediate repair area, eliminating the need for extensive rework.

Can molds made via 3D metal printing be repaired using these methods?

Yes. As additive manufacturing for tooling grows, repmold techniques are essential for maintaining them. Laser welding is particularly effective as it uses similar principles to how the 3D printed mold was originally constructed.

How does laser welding differ fundamentally from traditional arc welding in mold repair?

Traditional welding uses an electric arc to create a large molten pool, generating immense heat. Laser welding uses focused light energy to melt a tiny area instantly. The laser process is faster, cleaner, and transfers far less heat to the surrounding steel.

Is repmolding expensive compared to basic repairs?

While the hourly rate for advanced technology like laser welding is higher than a standard bench welder, the overall cost is often lower. This is because the precision prevents collateral damage (warping), saving countless hours of subsequent machining and polishing.

What types of tool materials can be treated?

Modern repmold technologies are highly versatile. They can effectively repair standard tool steels (like P20, H13, S7), stainless steels, aluminum alloys, and even specialized high-conductivity copper alloys used in molding.

How long does a typical high-tech repmold process take?

Timeframes vary by complexity, but many repairs that previously took weeks due to warping issues can now be completed in 24 to 48 hours, significantly reducing production downtime.

Does repmolding affect the final quality of the plastic part?

If done correctly using the proper metallurgy and finishing techniques, the repair should be invisible on the final molded part. The repaired area should have the same texture and polish as the rest of the mold.

Conclusion

The manufacturing landscape is shifting toward agility, efficiency, and digital integration. In this environment, regarding molds as disposable assets is economically obsolete. Advanced repmold technologies have transformed tooling maintenance from a crude necessity into a sophisticated strategic advantage. By leveraging laser precision, digital scanning, and metallurgical expertise, manufacturers can execute engineering changes faster, recover from damage cheaper, and extend the life of their most critical assets significantly. Embracing these high-tech repmold solutions is not just about fixing tools; it is about ensuring continuous, high-quality production in a demanding market. To stay competitive, evaluate your current tooling strategy and consider how integrating modern repair technologies can optimize your manufacturing footprint.