In the rapidly evolving landscape of the Internet of Things (IoT) and industrial automation, the devices that truly power our world often go unnoticed. We fixate on the latest smartphones or EVs, yet we rarely discuss the specialized controllers, rigorous educational standards, and precision components that make these technologies possible. Enter TEK-102 a designation that represents a critical intersection of smart control systems, industrial precision, and engineering education.

From managing complex solar heating arrays with smartphone apps to defining the standards of Computer-Aided Design (CAD) in technical colleges, TEK-102 is more than just a model number; it is a symbol of functional efficiency. Whether you are a facility manager looking to upgrade an automation system, an engineer seeking precision components, or a student entering the world of technical drafting, understanding the scope of TEK-102 applications offers a glimpse into the machinery that keeps the modern world running.

This comprehensive guide will demystify TEK-102, exploring its role as a cutting-edge solar controller, its significance in industrial machinery, and its foundational place in engineering curriculums. By the end, you will understand why this specific classification is vital for efficiency, sustainability, and technological advancement.

What is TEK-102? Defining the Technology

The term TEK-102 encompasses a specialized category of technical applications, most notably appearing as high-performance control units in renewable energy systems and precision industrial hardware. Unlike consumer gadgets designed for mass appeal, TEK-102 devices are engineered for reliability, durability, and specific task execution.

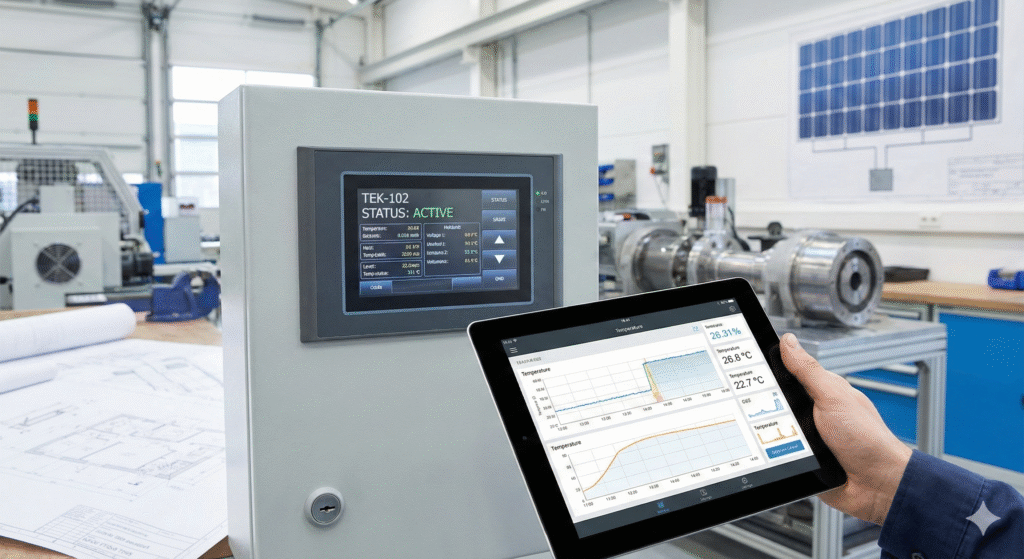

In the context of smart home technology, the TEK-102 series often refers to advanced differential temperature controllers, particularly those used in solar pool heating. These devices bridge the gap between raw hardware and modern digital interfaces, offering IoT (Internet of Things) connectivity that allows users to monitor thermal efficiency from their smartphones.

The Evolution of TEK-102 in Smart Automation

Automation has shifted from clunky, manual switchboards to sleek, digital interfaces. The TEK-102 architecture represents this leap. Modern controllers carrying this designation utilize sophisticated microprocessors to automate decision-making.

- Real-time Monitoring: Sensors continuously track environmental variables.

- Automated Logic: The system makes instant adjustments without human intervention.

- IoT Integration: Data is transmitted to the cloud for remote access and analysis.

This evolution means that a facility manager or homeowner no longer needs to physically check a gauge; the TEK-102 system notifies them of anomalies instantly.

The DTAC-102: A Prime Example of Solar Control

One of the most prominent real-world applications of this keyword is the DTAC-102 Solar Controller. This device is a powerhouse in the niche of aquatic thermal management. It is designed to optimize the efficiency of solar pool heating systems, ensuring that energy is captured only when it is most available and effective.

The DTAC-102 distinguishes itself with features that exemplify modern “Green Tech”:

- Winter Mode: Protects pipes from freezing by circulating water when temperatures drop.

- Tropical Mode: Prevents overheating in extreme climates.

- App Connectivity: Allows users to set temperatures and view pump status via mobile devices.

How TEK-102 Systems Optimize Energy Efficiency

Energy waste is a primary concern for both industrial and residential sectors. TEK-102 controllers address this by using “differential logic.” The system compares the temperature of the solar collector (the roof panel) against the water temperature.

The pump is activated only when there is a net energy gain to be made. If the roof is cooler than the pool (e.g., at night or during a storm), the TEK-102 system shuts down circulation to prevent heat loss. This precise logic can save property owners up to 30% on energy costs compared to timed or manual systems.

TEK-102 in Industrial Machinery: The EDM Sinker

Beyond smart controllers, the TEK-102 designation appears in heavy industry, specifically in Electrical Discharge Machining (EDM). The “Uni-Tek 102” series of EDM sinkers are legendary for their ability to machine complex shapes into hard metals that traditional drills cannot touch.

These machines use electrical sparks to mold metal, a process required for creating molds, dies, and aerospace components. The TEK-102 model in this sector is synonymous with:

- High Precision: Tolerances measured in microns.

- Durability: Built to run continuously in harsh workshop environments.

- Versatility: Capable of machining tungsten carbide and titanium.

The Educational Pillar: TEK-102 as a Course Standard

It is impossible to discuss TEK-102 without acknowledging its role in academia. In many engineering and polytechnic institutes, “TEK 102” is the code for foundational courses in Engineering Graphics and CAD (Computer-Aided Design).

This course is where future engineers learn the language of design. It covers:

- GD&T (Geometric Dimensioning and Tolerancing): The global standard for defining part geometry.

- 2D and 3D Modeling: Moving from blueprints to digital twins.

- Standardization: Learning how to draft schematics that can be read by manufacturers worldwide.

Key Features of TEK-102 Hardware Components

Whether referring to a controller or a machine part, hardware designated with TEK-102 often shares a set of rugged characteristics designed for industrial longevity.

- IP Ratings: Many TEK-102 controllers are rated IP65 or higher, ensuring they are dust-tight and water-resistant.

- Thermal Resistance: Components are built to withstand extreme temperature fluctuations found in attics or factory floors.

- Universal Compatibility: Designed to retrofit into existing systems (e.g., replacing an old mechanical timer with a digital TEK-102 unit).

Installation and Setup of TEK-102 Controllers

Installing a TEK-102 solar controller requires a blend of plumbing and electrical knowledge. It serves as the “brain” of the heating loop.

- Sensor Placement: One sensor is mounted on the roof (solar collector) and another in the water feed pipe.

- Actuator Connection: The controller is wired to the motorized valve that directs water flow.

- Calibration: The user sets the desired temperature differential (usually 6-8 degrees) to ensure the pump doesn’t cycle on and off too rapidly (a phenomenon known as “short cycling”).

Semantic Connectivity: TEK-102 and IoT

The “Information” aspect of TEK-102 shines in its connectivity. Modern units act as edge devices in a larger IoT network.

| Feature | Traditional Controller | TEK-102 IoT Controller |

| Interface | Analog Dials | Touchscreen / Smartphone App |

| Data Logging | None | Historical Temperature Graphs |

| Alerts | None | Push Notifications for Faults |

| Updates | Hardware Replacement | Over-the-Air (OTA) Firmware Updates |

Troubleshooting Common TEK-102 Issues

Like any sophisticated technology, TEK-102 systems can encounter issues, usually related to sensors or power supply.

- Sensor Errors: If the roof sensor cable is damaged by UV exposure, the system may read -40°F and refuse to turn on.

- Connectivity Drops: IoT versions may lose Wi-Fi connection if installed in a metal shed (Faraday cage effect).

- Valve Sticking: In hard water areas, the motorized valve controlled by the TEK-102 can seize, requiring maintenance.

The Role of TEK-102 in Predictive Maintenance

Advanced TEK-102 systems are now incorporating predictive maintenance algorithms. By analyzing the current draw of the pump or the speed of temperature change, the controller can predict a failure before it happens.

For example, if the water temperature rises slower than usual despite full sun, the TEK-102 system might flag a potential blockage in the filter or a leak in the roof panels, alerting the user to inspect the system.

Comparative Analysis: TEK-102 vs. Competitors

When comparing TEK-102 based controllers to generic alternatives like the standard “Goldline” or “Pentair” basic models, the difference often lies in the user interface and customization.

Generic models often have “set and forget” interfaces that are difficult to adjust. TEK-102 units prioritize granular control, allowing users to define hysteresis loops, lock-out times, and even integrate with home automation systems like Crestron or Control4.

Future Trends for TEK-102 Technologies

The future of TEK-102 lies in AI integration. The next generation of these controllers will likely use weather forecast data to make smarter decisions.

Imagine a TEK-102 controller that sees a storm approaching tomorrow. It might decide to overheat the pool slightly today (thermal banking) to ensure the water remains warm through the cloudy days ahead without using backup gas heaters. This level of “anticipatory automation” is the next frontier.

Pricing and Availability

The cost of TEK-102 hardware varies significantly by application.

- Solar Controllers: Generally range from $300 to $600, depending on Wi-Fi capabilities.

- Industrial Components: Used EDM machines or cylinder heads can range from $1,000 to $15,000.

- Educational Materials: Course fees and textbooks for TEK 102 modules typically run in the hundreds.

Integration with Green Building Standards

Using TEK-102 certified or rated equipment contributes to Green Building certifications such as LEED. Automated controls that reduce energy consumption are high-scoring credits in these frameworks.

By ensuring pumps run only when necessary, a TEK-102 controller minimizes the carbon footprint of a facility, aligning with global sustainability goals (SDGs).

Security Protocols in TEK-102 IoT Devices

With great connectivity comes great responsibility. TEK-102 IoT devices must adhere to strict security standards to prevent unauthorized access.

- Encryption: Data between the app and the controller is encrypted via TLS 1.2 or higher.

- Local Control: Many units offer a “Local LAN” mode, allowing control without sending data to an external cloud server, enhancing privacy.

Why Technical Education (TEK-102) Matters

The hardware is only as good as the engineer who designs it. This brings us back to TEK-102 as a course. The rigor of these educational programs ensures that the engineers of tomorrow understand the physics of thermodynamics and the precision of GD&T.

Without the foundational knowledge taught in TEK-102 classrooms, the innovations seen in TEK-102 hardware would not exist. It is a symbiotic relationship between education and application.

Conclusion: The TEK-102 Advantage

The keyword TEK-102 serves as a fascinating portal into the world of technical specificity. It represents the “hidden tech” that optimizes our energy usage, the heavy machinery that builds our world, and the educational pathways that train our innovators.

Whether you are installing a DTAC-102 to manage your pool’s solar heating or studying for a TEK 102 final exam on AutoCAD, you are engaging with a standard of excellence. In a world that demands higher efficiency and smarter data usage, TEK-102 technologies offer a robust, reliable, and intelligent solution. Embracing these systems is not just about upgrading hardware; it is about adopting a mindset of precision and sustainability.

FAQs

What is the primary function of a TEK-102 solar controller?

A TEK-102 solar controller (like the DTAC-102) automatically manages the flow of water through solar panels. It uses temperature sensors to ensure the pump only runs when the solar collectors are hotter than the pool water, maximizing energy efficiency and preventing heat loss.

Can TEK-102 devices connect to Wi-Fi?

Yes, modern iterations of TEK-102 controllers often feature Wi-Fi or Bluetooth connectivity. This allows users to monitor temperatures, change settings, and receive alerts via a dedicated smartphone app, integrating the device into the wider smart home ecosystem.

Is TEK-102 a software or hardware product?

TEK-102 primarily refers to hardware (controllers, industrial components) or an educational course code. However, the hardware often includes embedded firmware and companion software apps for control and monitoring, bridging the gap between hardware and software.

What does the “TEK 102” engineering course cover?

In an academic context, TEK 102 typically covers “Engineering Graphics” and “Introduction to CAD.” Students learn 2D drafting, 3D modeling, and Geometric Dimensioning and Tolerancing (GD&T), skills essential for manufacturing and design careers.

How does a TEK-102 controller save money?

By using differential temperature logic, a TEK-102 controller prevents the pool pump from running unnecessarily (such as on cloudy days) and prevents the system from cooling the pool by circulating water at night. This precise control can reduce pump electricity costs and heating bills significantly.

Are TEK-102 industrial components compatible with other brands?

Generally, yes. Industrial components with the TEK-102 designation (like valves or cylinder heads) are often built to standard industry sizes (e.g., Small Block Chevy engines for heads). However, it is crucial to check specific datasheets for bolt patterns and flow rates before installation.

What should I do if my TEK-102 controller displays a sensor error?

A sensor error usually indicates a break in the wire or a failed thermistor. Check the cable running to the roof for damage from rodents or UV exposure. Most TEK-102 units use standard 10k Ohm thermistors, which are inexpensive and easy to replace.